An analysis tool for better understanding and advising

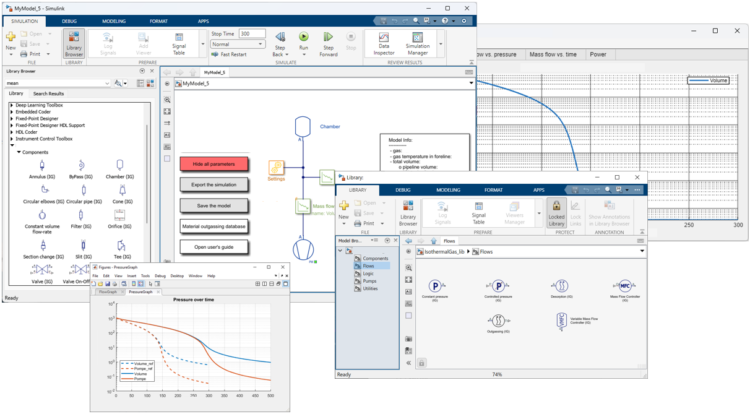

To facilitate the analysis of results, a visualisation and post-processing tool specific to the profession has been developed. It automatically plots pressure curves, compares pumping times obtained between different scenarios, and identifies potential bottlenecks in the installation. The interface has been designed to guide users in interpreting the results, even without in-depth expertise in physical modelling.

Finally, a customer study management tool has been integrated, allowing different installation configurations to be saved, replayed and compared. This enables application engineers to respond quickly and knowledgeably to customer requests, while capitalising on the information for future studies.

This project illustrates how a business-oriented approach, combined with Simulink and Simscape software, can be used to create high value-added tools for technical and sales teams. Such a workshop facilitates the design of convincing sizing proposals that are calculated as accurately as possible and offer validated performance.