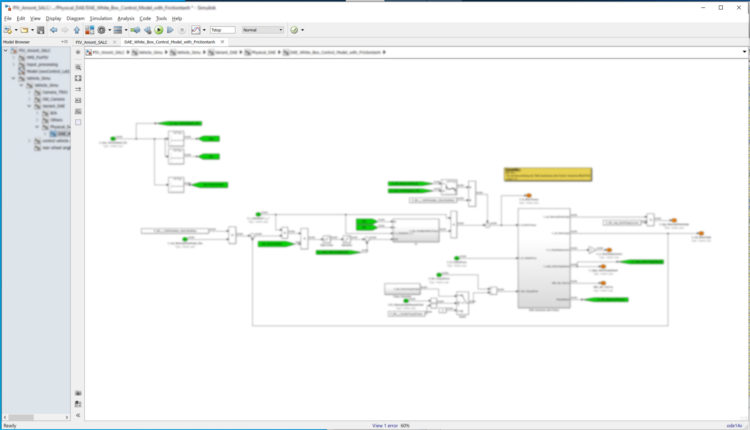

To solve this issue, Acsystème applied a modelling and simulation approach: Model Based Design. This method consists of modelling the manufacturing process on a computer, and testing various settings, even the explosive ones, in simulation. without any interruption of manufacturing. We therefore modelled all the chemical process components (neutraliser, storage tanks) unitarily with their related regulation systems in Matlab and Simulink. Then, the overall equipment was modelled by interconnecting the various components. The resulting model was then validated in simulation, by comparing simulation results with on-site measurements.