When robots play Tetris

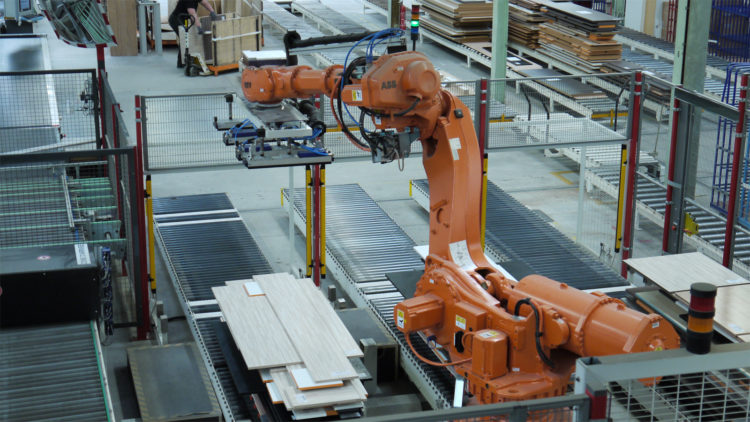

In the current industrial world, task automation is a way to save valuable time for manufacturing products, managing stocks and preparing packages. In most cases, products are all the same and palletisation is automated.

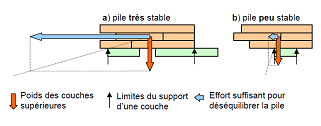

However, sometimes they are all different: size, shape and weight. In that case, it is a real challenge to realise a stable and optimal stack, and operator intervention is often required.

Technic Automation and Acsystème wanted the automation of this task thanks to a robotised system and an embedded calculation algorithm. This solution is a gain in productivity and improves work safety by relieving operators from hard and physical tasks.